It’s 2023 – another year closer to the deadline for achieving the UN’s SDGs (Sustainable Development Goals)! As the 2030 target date draws ever nearer, we’re exploring SDG 12 in further detail – discussing why this particular goal is more relevant than ever, and how creating sustainable supply chains can help us meet this objective.

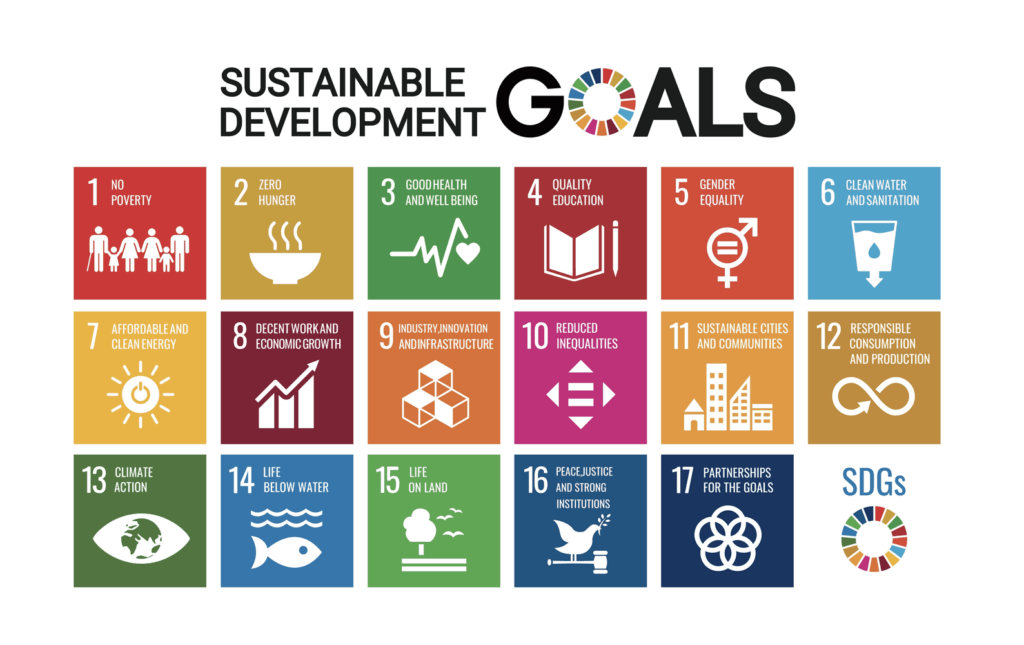

The Sustainable Development Goals – or Global Goals – are a collection of interlinked objectives created by the United Nations, designed to serve as a “shared blueprint for peace and prosperity for people and the planet now and into the future”.

There are 17 goals in total, each created to emphasise the interconnected environmental, social and economic aspects of sustainable development. The SDGs include everything from poverty and world hunger, through to gender equality, education, clean energy and much more. The deadline for most of these targets is 2030 – although it is worth noting that some have no definitive end date.

The SDGs were adopted by 193 countries of the UN General Assembly as part of the 2030 Development Agenda. This marked a significant milestone, as it demonstrated a collective global acknowledgement of the need to drive sustainable change from a financial, social and environmental perspective.

This means that all businesses – regardless of size – should be taking responsibility for their carbon footprint by actively trying to minimise the environmental impact of their operations.

Efforts like this can be seen as directly linking to the aims of Goal 12 of the SDGs – namely “Responsible Consumption and Production”.

This goal aims for an improvement in how we can manage our natural resources more efficiently by disposing of waste better, cutting food waste in half globally and getting businesses and consumers to reduce and recycle waste.

An effective method of doing this is by encouraging and implementing responsible consumption and production habits across the supply chain.

Given that the typical consumer company’s supply chain accounts for more than 80% of greenhouse-gas emissions[1], it makes sense that this area should be prioritised in the journey towards true sustainability.

There’s currently no legal obligation for businesses to contribute to or operate in ways that are conducive to achieving SDGs.

However – sustainability is a progressively pertinent issue in the business world and has become a crucial element of many organisations’ strategies and values. In addition to having the potential to improve efficiency and cut down costs, being sustainable also brings wider benefits from a reputational and commercial perspective.

As we move towards a future marked by specific sustainability goals, clients, customers and other stakeholders are increasingly looking to work with environmentally friendly organisations that can validate their sustainability claims. Acknowledging the SDGs in mission statements or engaging in business practices and projects that are conducive towards them can then be highly beneficial for organisations looking to grow and succeed.

Working in ways that are beneficial to the SDGs is also ethically the right thing to do.

This is especially true considering the central role that businesses play in climate change, where in the UK it is estimated that business activities account for about half of all greenhouse gas emissions.[2]

Before you can instigate sustainability across the supply chain, you need to measure it.

It’s impossible to identify which areas or third-party suppliers in the supply chain need to be improved without having access to meaningful and accurate data. Being able to easily and accurately measure your businesses carbon footprint or collect key emissions data (such as scope 1, 2 and 3) is therefore a highly effective way of starting to improve supply chain sustainability.

This information equips you with the knowledge necessary to change or implement operations that are beneficial to encouraging responsible production and consumption habits in your business.

In practice, this could look like investing in new machinery which is less damaging to the environment or switching suppliers. It also could involve engaging with carbon offsetting or insetting schemes initiatives or supporting third-party suppliers in improving their operations and environmental impact. This, in turn, can increase the efficiency and sustainability of the overall supply chain.

At AXIOM, we help businesses implement sustainable production patterns by creating sustainable supply chains.

We provide organisations with full visibility over the data that matters using our carbon reporting software which seamlessly collates emission data across the year, accurately reports on scope emissions and automatically calculates GHG emissions.

Looking to make your supply chain more sustainable? We can help.

Get in touch with our team to book your free demo here.

[1] Starting-at-the-source-Sustainability-in-supply-chains.pdf (mckinsey.com)

[2] SMALL BUSINESS USER GUIDE: Guidance on how to measure and report your greenhouse gas emissions (publishing.service.gov.uk)

Want to know more? Please get in contact with our team here.

Contact Us